Why Choose CarboSeal?

A robust product that works

Built for Tough Conditions

Verified

Offer Support

Special thermoplastic foil guarantees steam curing and subsequent removal with no issues.

Proprietary version of TeXtreme fabric guarantees high-quality cured liner, free of microcracks and matched to host-pipe heat expansion properties.

Unique resin can withstand operating temperatures of up to 130°C over a long period of time. Applied using a proprietary process to produce a void-free liner.

Special thermoplastic foil guarantees smooth and safe product installation and handling.

Host pipe made of steel.

For more information hover / click on the round buttons.

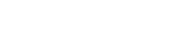

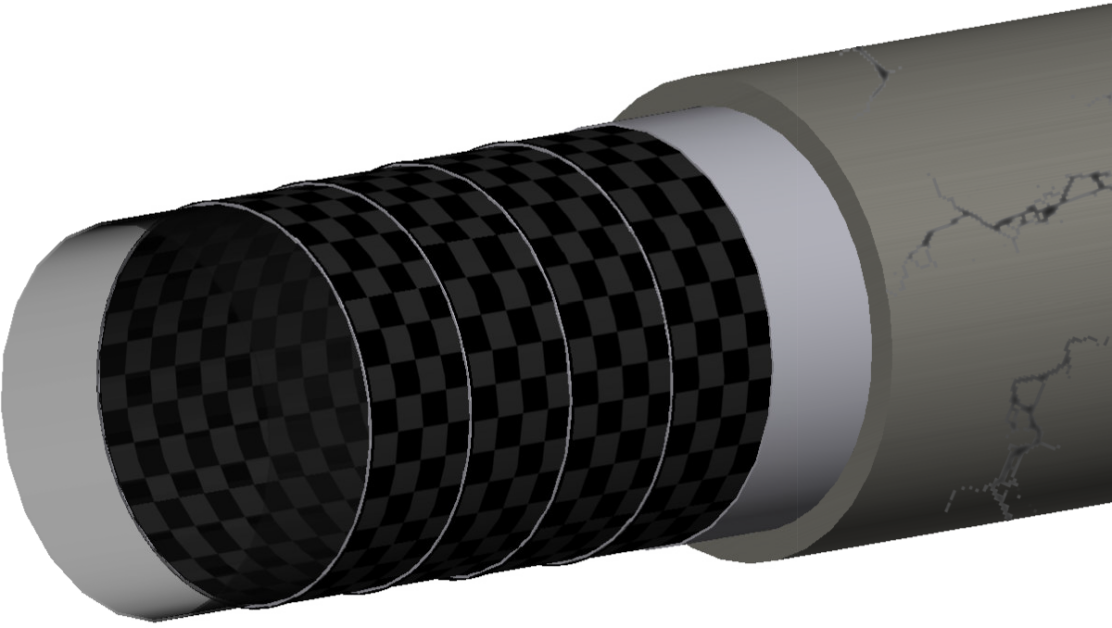

The Layers of the Liner

1. Inner film

Special thermoplastic foil guarantees steam curing and subsequent removal with no issues.

2. Multiple carbon fiber layers

Proprietary version of TeXtreme fabric guarantees high-quality cured liner, free of microcracks and matched to host-pipe heat expansion properties.

3. Resin

Unique resin can withstand operating temperatures of up to 130°C over a long period of time. Applied using a proprietary process to produce a void-free liner.

4. Outer film

Special thermoplastic foil guarantees smooth and safe product installation and handling.

5. Host pipe

Host pipe made of steel.

CarboSeal® References

Efficient Rehabilitation by Sundsvall Energi in Sundsvall: CarboSeal Liners in Action

Read more ReferencesOur Offer

A Unique Solution

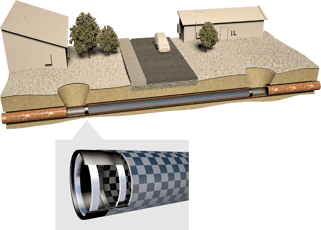

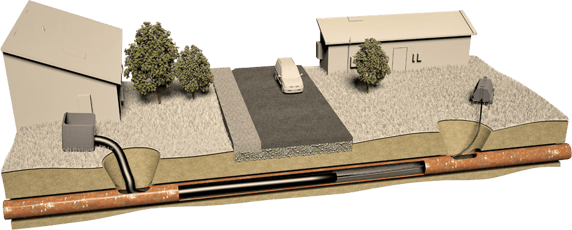

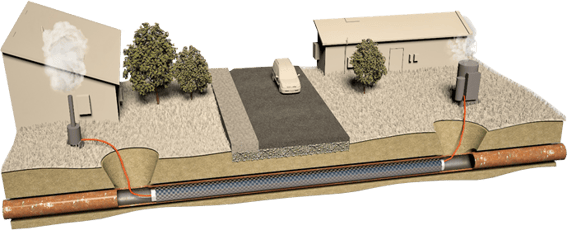

CarboSeal is a unique solution for replacing subterranean service pipes and structures with little or no excavation.

Non-Invasive

The entire underground pipe system is renewed without disturbing the activities above the pipe. Traffic, businesses, and other activities is left uninterrupted during the process. It is a fast, cost efficient solution for district heating pipe system rehabilitation.

Long-Lasting

CarboSeal is a composite of carbon fibre and high temperature epoxy resin. The epoxy resin has been developed to withstand high temperatures in wet conditions and is combined with a type of carbon fibre that is not affected by water. This material system has been developed to withstand high-pressure, high-temperature and corrosive environments over time.

- Flow capacity is maintained or increased thanks to a lower surface roughness

- Environment is spared with a trenchless renewal – CO² emissions are reduced by up to 80%

Developed for Tough Conditions

CarboSeal has been developed to handle the tough conditions found in district heating networks and can deal with temperatures of 130 °C and 16 bar pressure or more.The use of an epoxy developed for high temperatures in wet environments in combination with a carbon fiber unaffected by water gets around problems that arise with traditional liners. At present, we offer CarboSeal for dimensions from DN 150 to DN 800.

What we are offering

A Verified & Supported Product

CarboSeal is a unique solution for replacing subterranean service pipes and structures with little or no excavation.

- Withstands hydrolysis

- No loss of fiber surface properties over time

- Long-term resistance to high-temperature water

- Withstands pressures exceeding 16 bar

Verified

Thorough research conducted by the Research Institute of Sweden (RISE) and partners at PPR demonstrates CarboSeal's capacity to overcome challenges faced by traditional trenchless technologies in district heating pipe applications.

While long-term testing poses a challenge, it serves as a testament to the durability and reliability of CarboSeal®. Our extensive testing has shown promising results, indicating that CarboSeal® can maintain integrity for at least 40 years under standard district heating conditions.

Capable of withstanding temperatures up to 130°C and pressures of 16 bar or more, CarboSeal® harnesses a unique epoxy and carbon fiber blend tailored for high heat, pressure, and corrosive conditions, enhancing district heating solutions.

At CarboSeal® we have been fortunate to collaborate with exceptional partners globally, enriching our mission with diverse expertise.

CarboSeal® is operational in seven countries worldwide, undergoing rigorous testing in various environments and proving its benefit and reliability repeatedly.

Support

CarboSeal offers support from our team dedicated to installing and maintaining our products. For new installers, we offer a well-established certification and education program containing online, on-site, and ground training. Our installation team collaborates with qualified customers to troubleshoot and ensure a smooth process.

Our commitment extends beyond providing solutions—we are dedicated to supporting you from the start. During the design and planning stages, we collaborate closely with customers and installers, maximizing CarboSeal's potential. Together, we thoroughly examine critical points in your network.

In cases where longer sections require renewal, we explore combining CarboSeal with new piping for the most efficient solution. We recognize limited resources and the urgency of replacements, offering a faster, cost-effective approach without compromising quality. Let's collaborate to optimize your network and ensure it functions optimally for at least 40 years.

How it Works

5 Steps to the Renewal

Cleaning the Host Pipe

Start by cleaning the host pipe to remove foreign objects, welding residues, sediments etc.

![CarboSeal-Cleaning[1]](https://carboseal.com/hs-fs/hubfs/cs2023/images/CarboSeal-Cleaning%5B1%5D.png?height=230&name=CarboSeal-Cleaning%5B1%5D.png)

Video and Dimension Control

Inspect to ensure secure pull-in and installation of the liner.

Pull in the Liner

The liner is pulled in by winch on a protective film. Several hundred metres of pipe can be renewed in one shot.

Curing with Steam

After the liner is pulled in, pressurized steam is applied, which unfolds and hardens the liner against the host pipe.

Connecting the Renovated Pipe

Special couplings are used to seal the transition between liner and host pipe. Air is used to perform a leakproofing test before sealing the openings by welding.